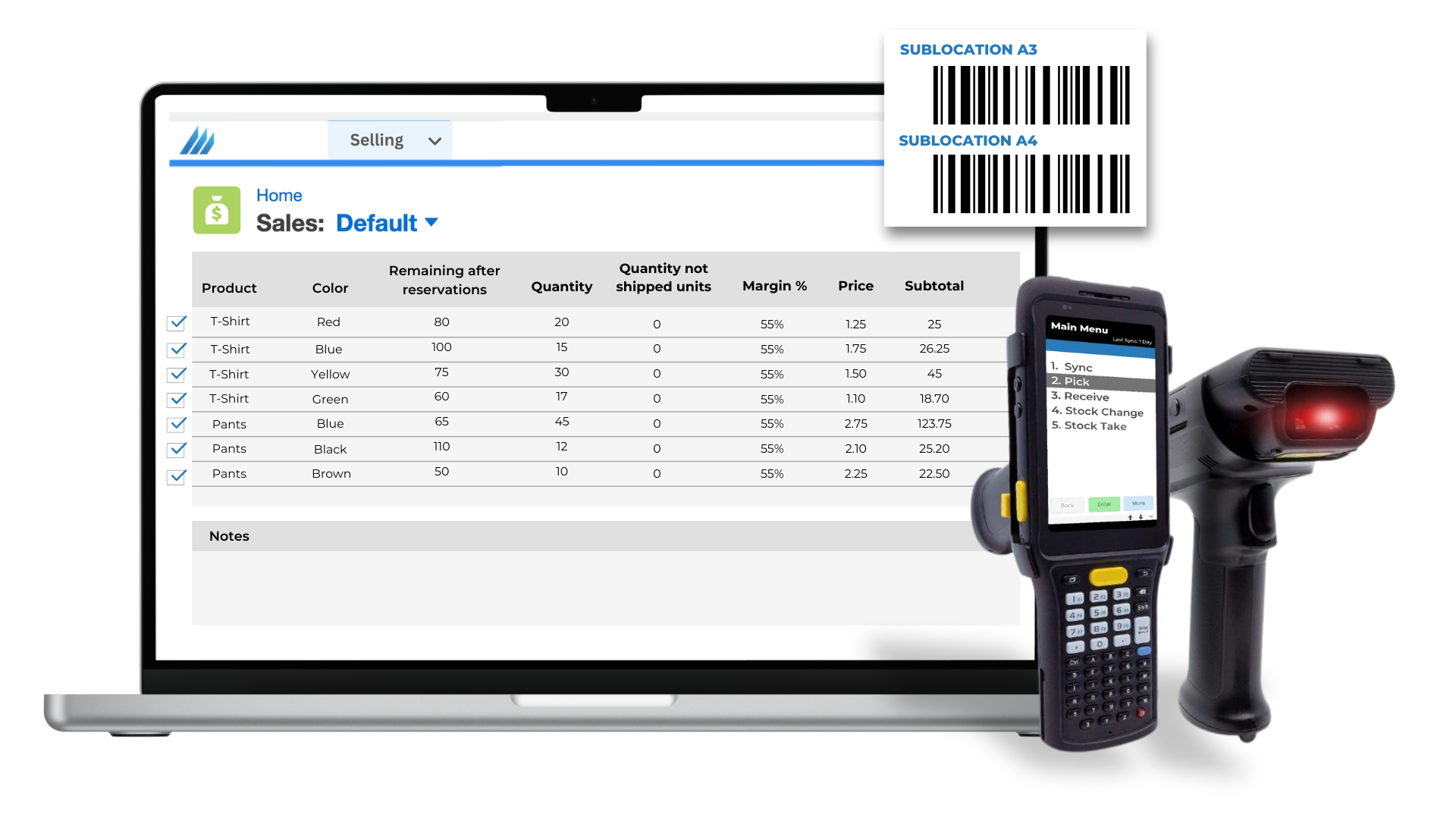

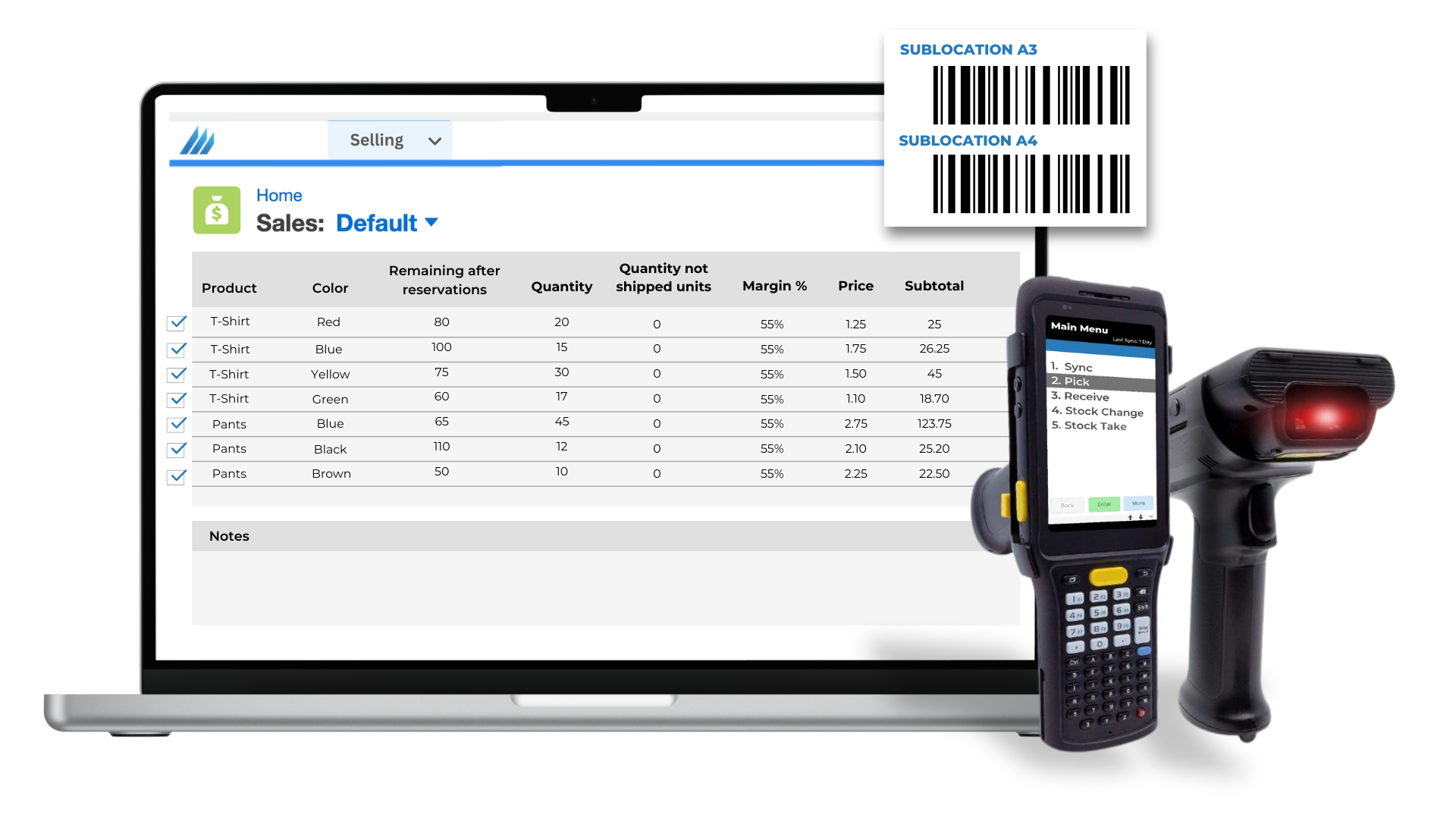

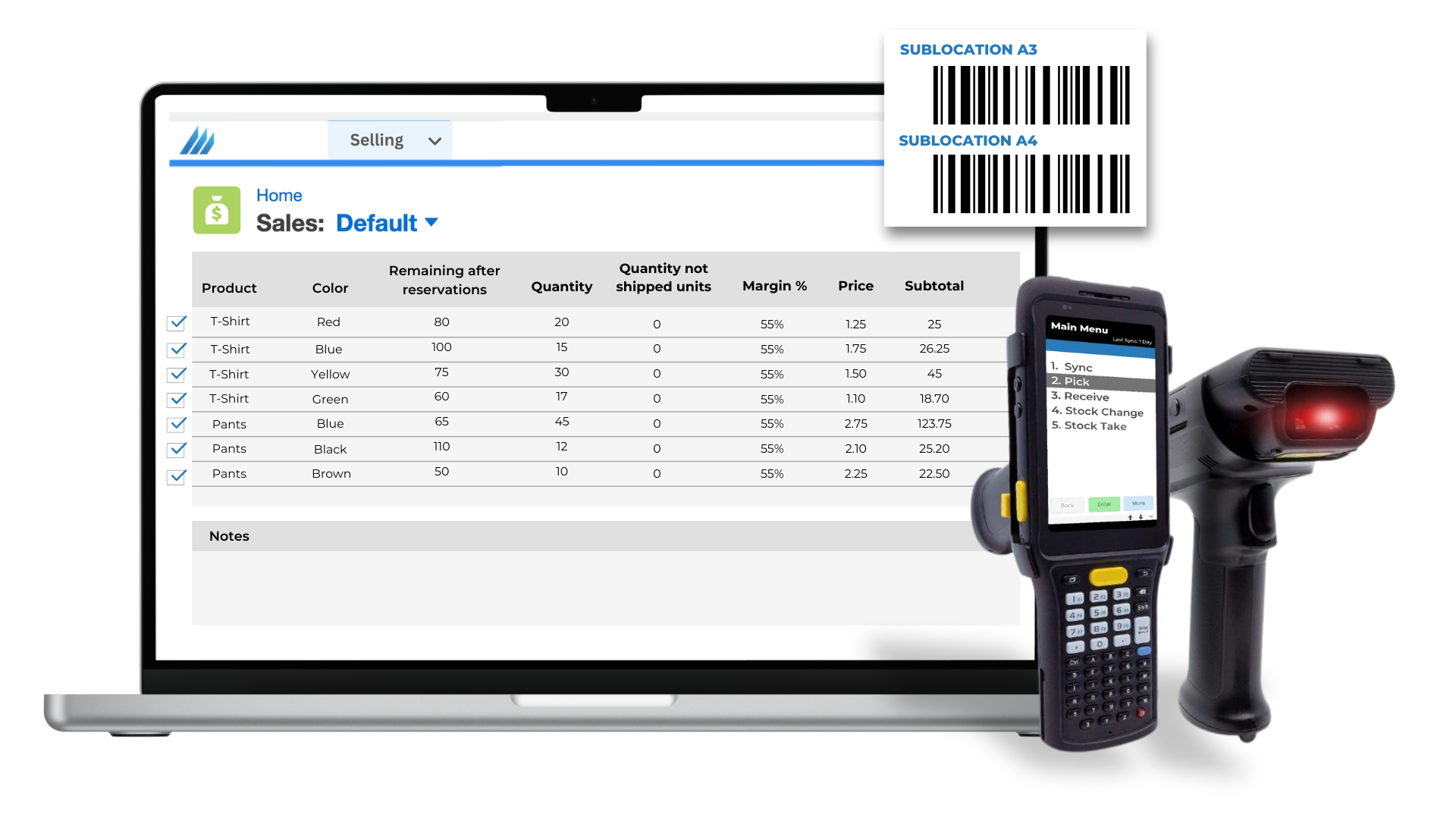

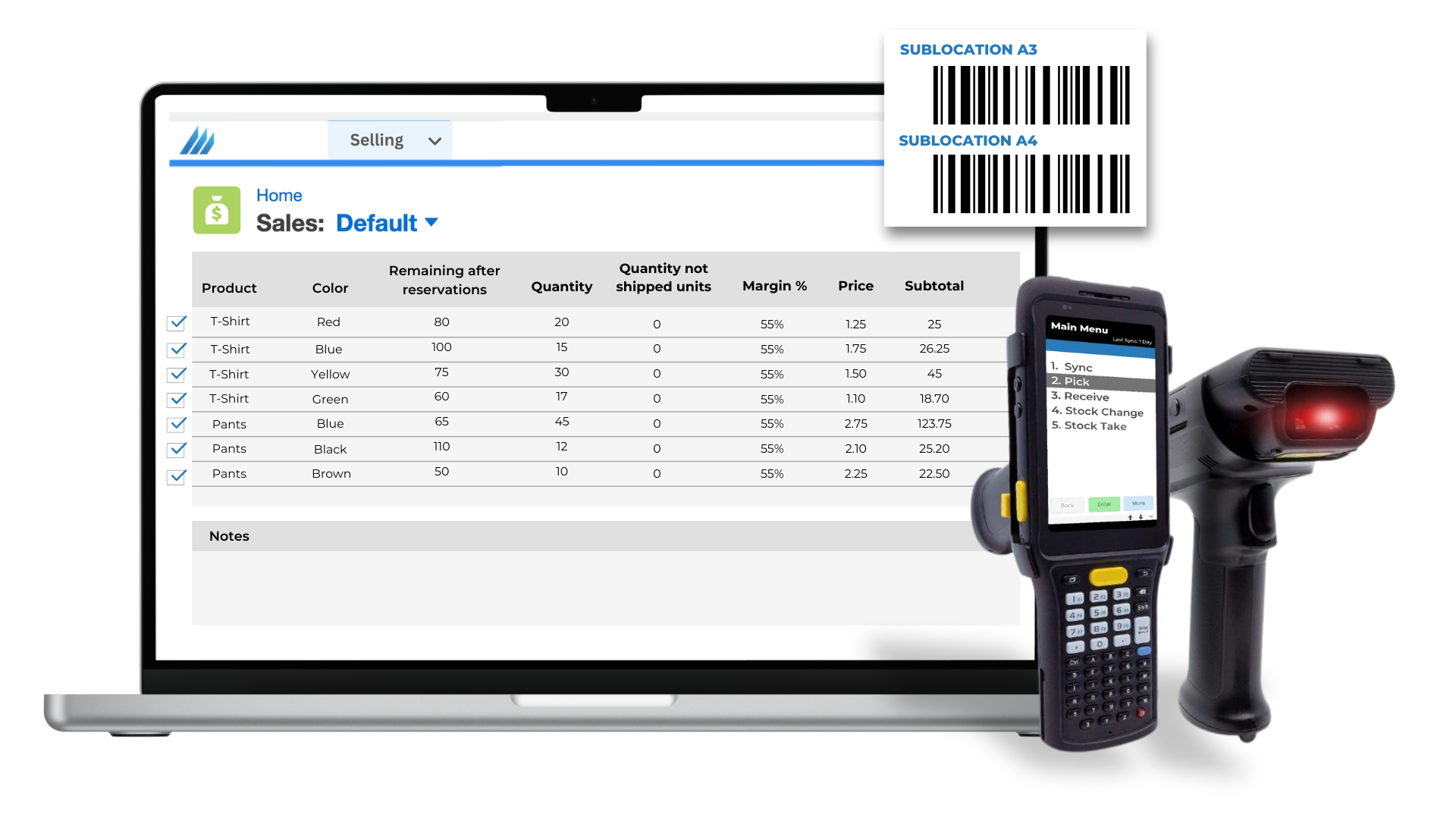

Wave Picking with a Mobile Barcode Scanner

Boost efficiency, accuracy, and visibility in your warehouse with barcode-powered picking tools

Finale Inventory's wave picking software automates your entire order-picking workflow, seamlessly connecting with your existing ecommerce, WMS, and other critical business systems.

Multiple and High-Volume Order Fulfillment

What is Wave Picking?

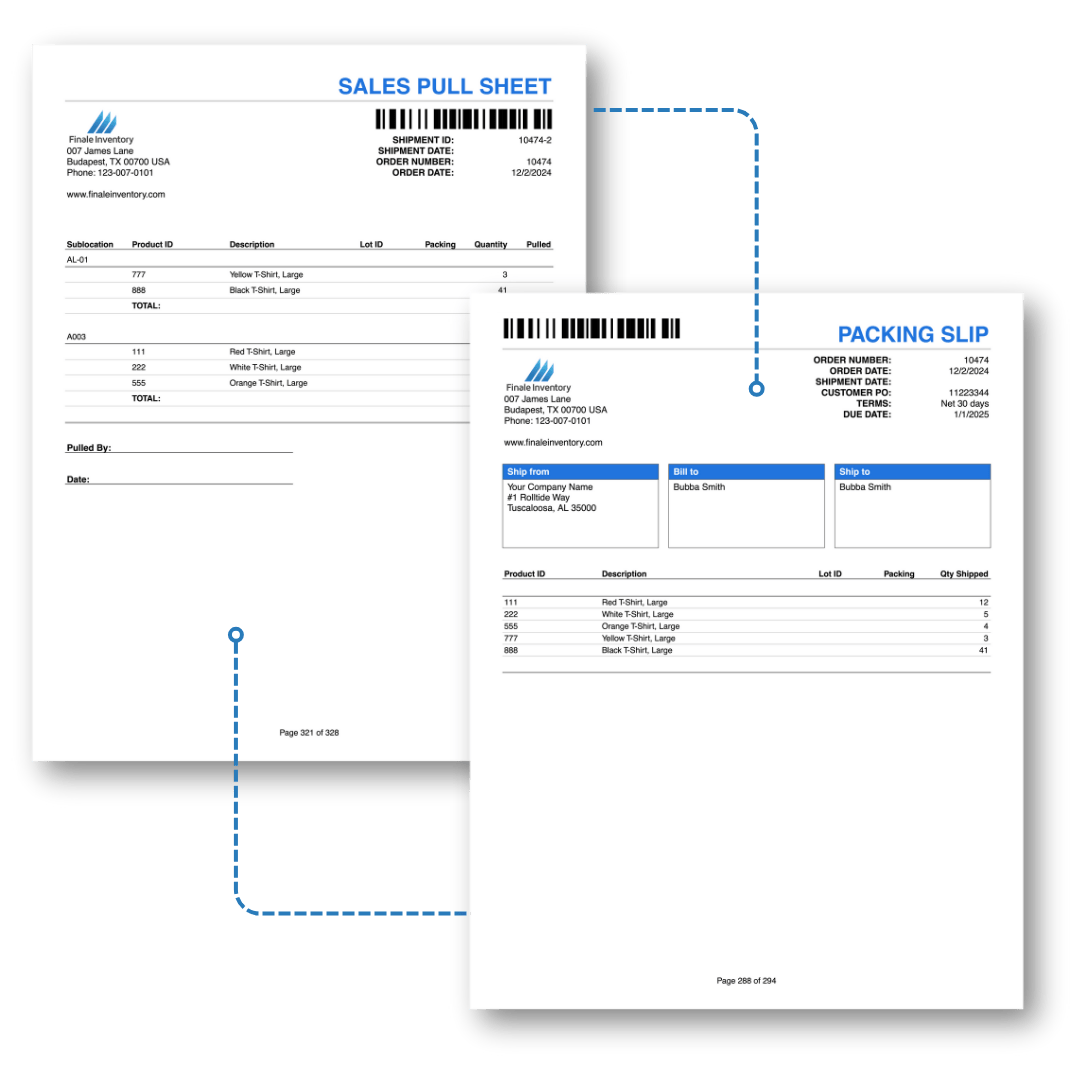

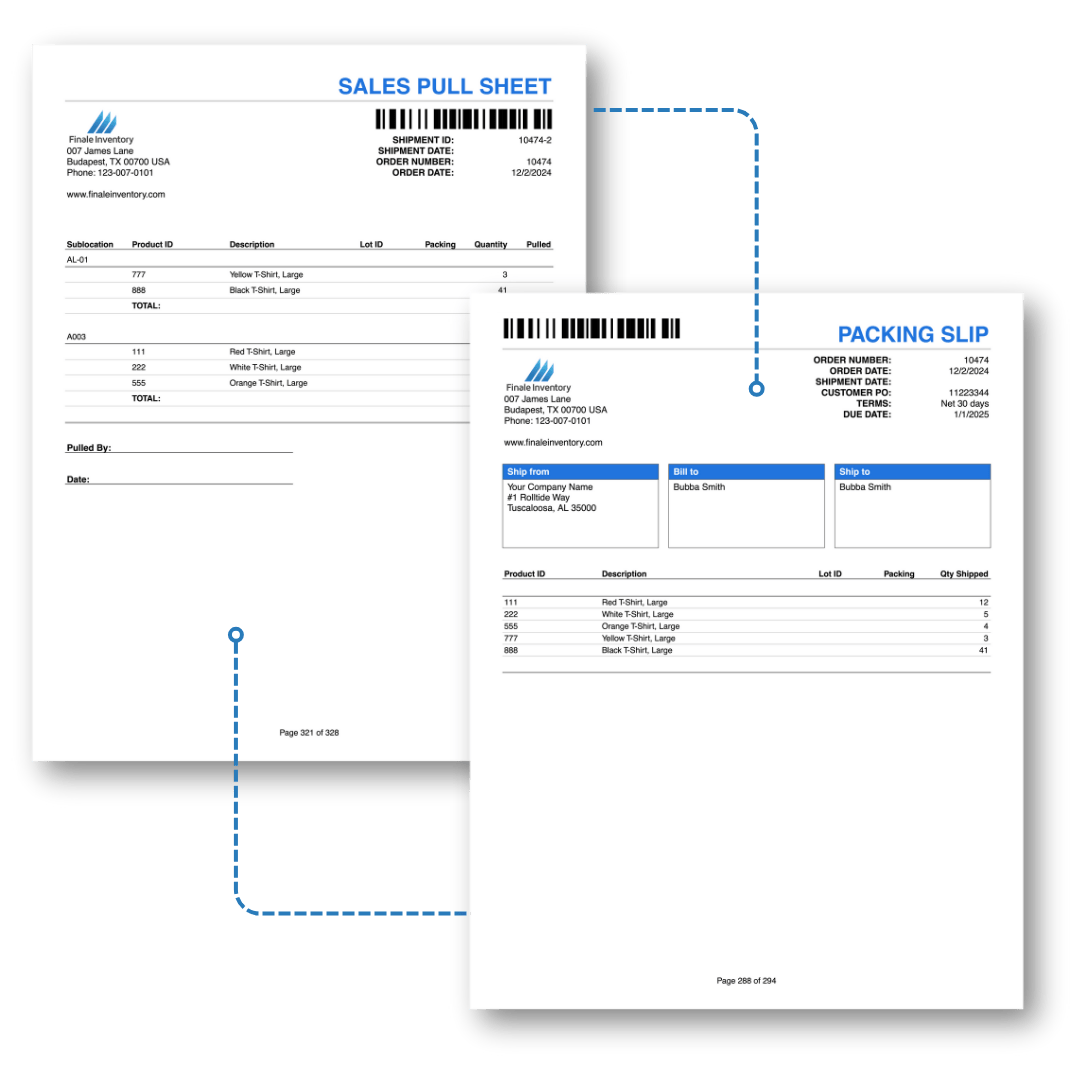

Wave picking involves combining similar orders into a batch and pulling the inventory for all orders simultaneously. The idea is to reduce the number of picking trips required. These batches can be defined according to several factors—priority, shipping carrier, location, and more—according to the needs of your operation.

As an example of wave picking leveraging a mobile barcode scanner, you could plan to pick all orders due to be shipped at a particular time using the same carrier all at once. You can also pull all the pending shipments that contain an SKU in a particular zone of the warehouse. Both of these strategies can improve operational efficiency for a warehouse, depending on your business needs. Some warehouses enhance wave picking by scheduling them precisely to ensure on-time fulfillment.

Stop Struggling with Slow Order Fulfillment and Frequent Shipping Delays

Eliminate manual data entry errors and increase worker productivity with instant, barcode-driven picking and verification

Save Time Wasted on Unnecessary Walking

Optimize order fulfillment by dynamically organizing and sequencing picks based on bin locations to minimize travel time. Watch the video overview of wave picking to learn more.

Clean Up the Disorganized Workflows and Missed Priorities During Peak Times

Integrate barcode scanning with your other systems for a unified, end-to-end workflow that improves visibility and efficiency. Scale to support growing businesses with flexible cloud-based deployment, customizable features, and easy expansion

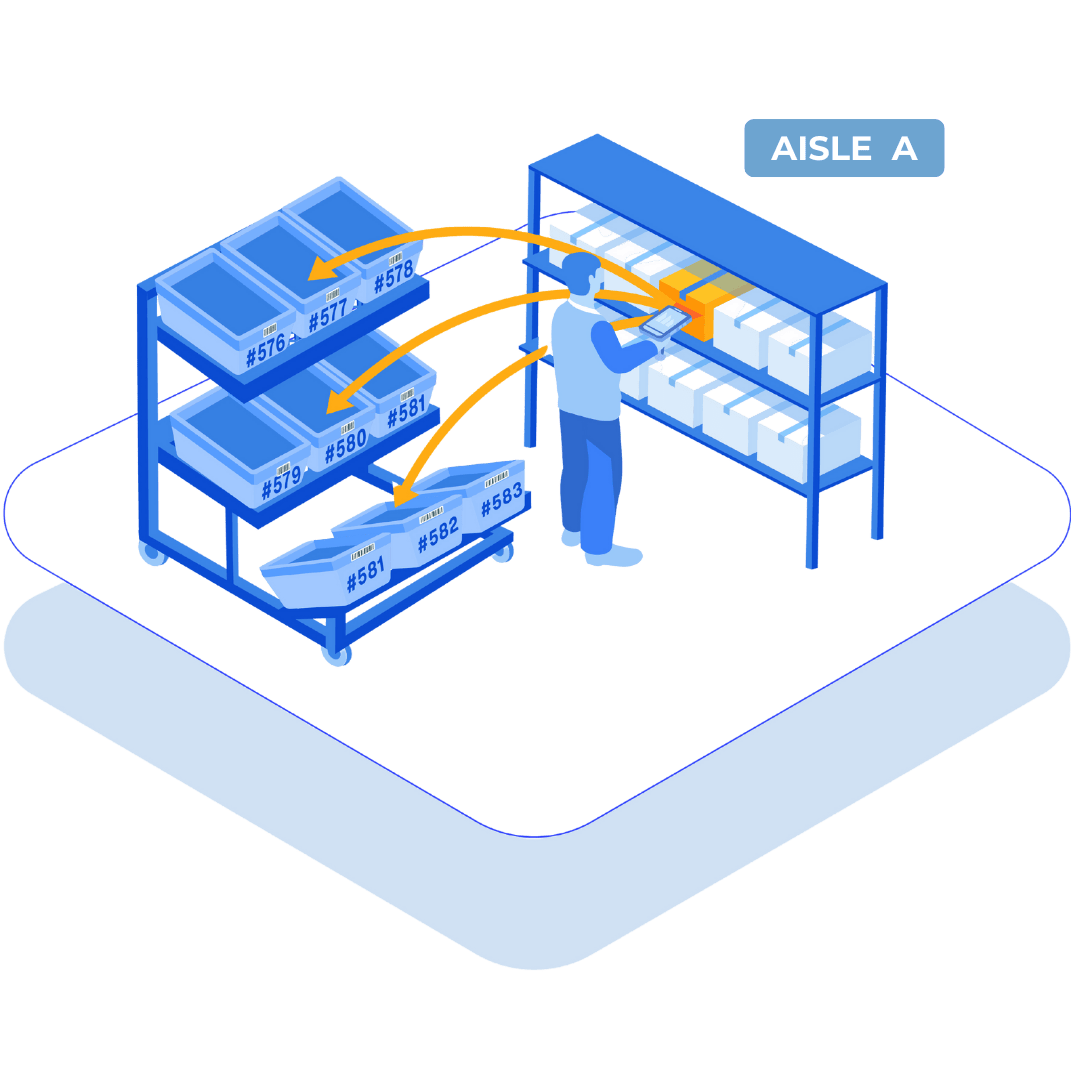

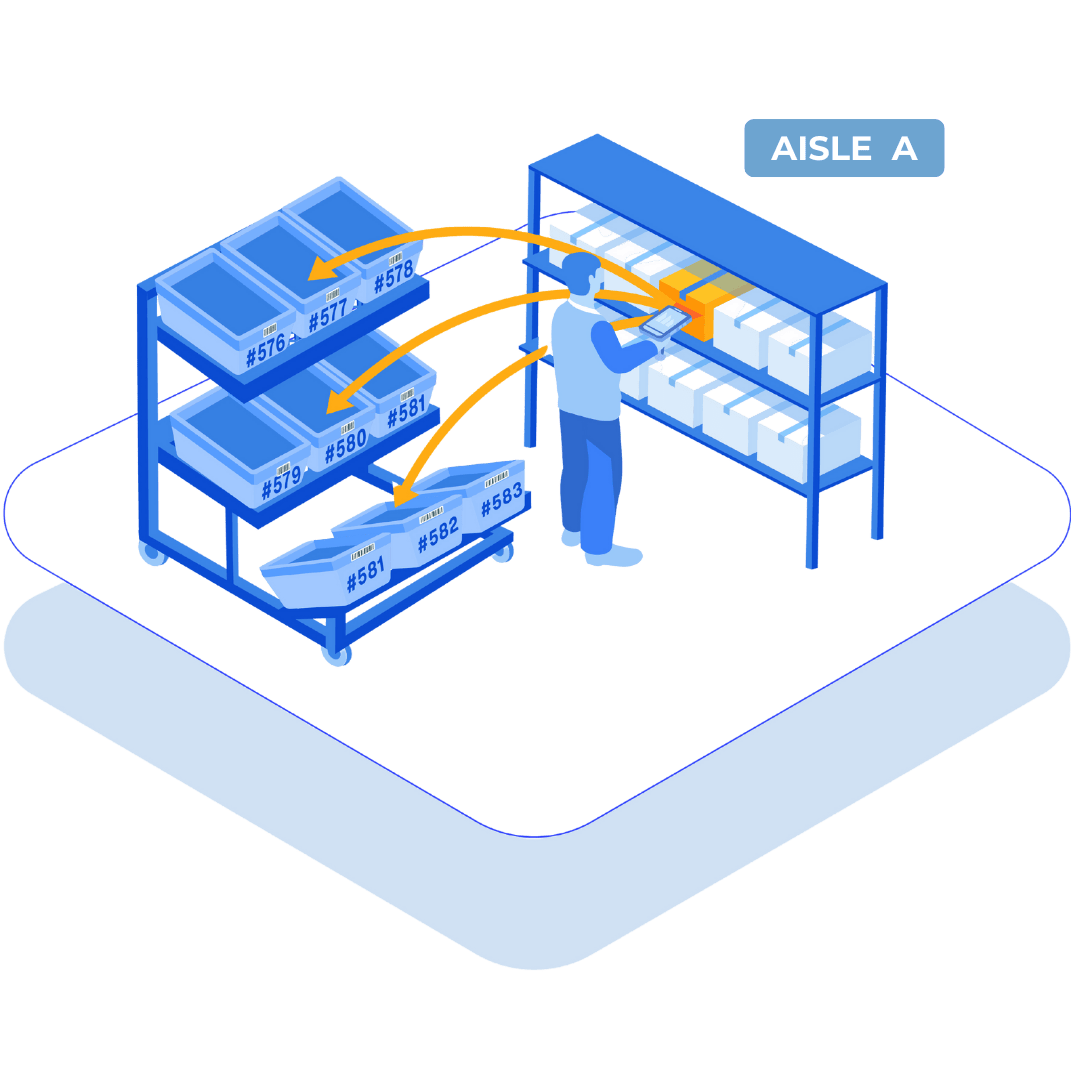

Never mix up orders with slot IDs. Finale's wave picking solution uses slot IDs for each bin on the cart as a temporarily stored spot or organized during the picking process.

When using the wave picking strategy, items for multiple orders are picked together in a batch, and slot IDs help separate and organize these items by order or destination.

Finale Inventory. The Ultimate Wave Picking System.

Wave Picking vs Basic Picking

Wave picking involves picking items for multiple orders in a single batch, optimizing efficiency for high-volume operations. Items are often grouped by location or priority, with Slot IDs used to organize orders for accuracy during packing. In contrast, basic single-order picking focuses on fulfilling one order at a time, ensuring simplicity and reducing potential errors. While single-order picking suits smaller operations or unique orders, wave picking is ideal for businesses handling large order volumes and requiring faster processing.

Customizable Wave Picking Strategies

Finale allows warehouses to define picking waves based on various criteria such as order priority, shipping carrier, or warehouse zones. This flexibility enables businesses to tailor the wave picking process to their specific operational needs, optimizing efficiency and aligning with shipping schedules.

Error Prevention in Real-Time

Scan-based verification ensures every item picked is correct by requiring a barcode scan to confirm it matches the order. If an incorrect item is scanned, the system immediately alerts the picker, preventing errors before they happen.

Watch the video here on wave picking on the barcode scanner.

This can be done in the barcode tab at the top of the screen, then click print barcode labels. Then, choose print label sequence.

In the main menu, you will see a list of all the picking methods. Scroll until you see wave picking.