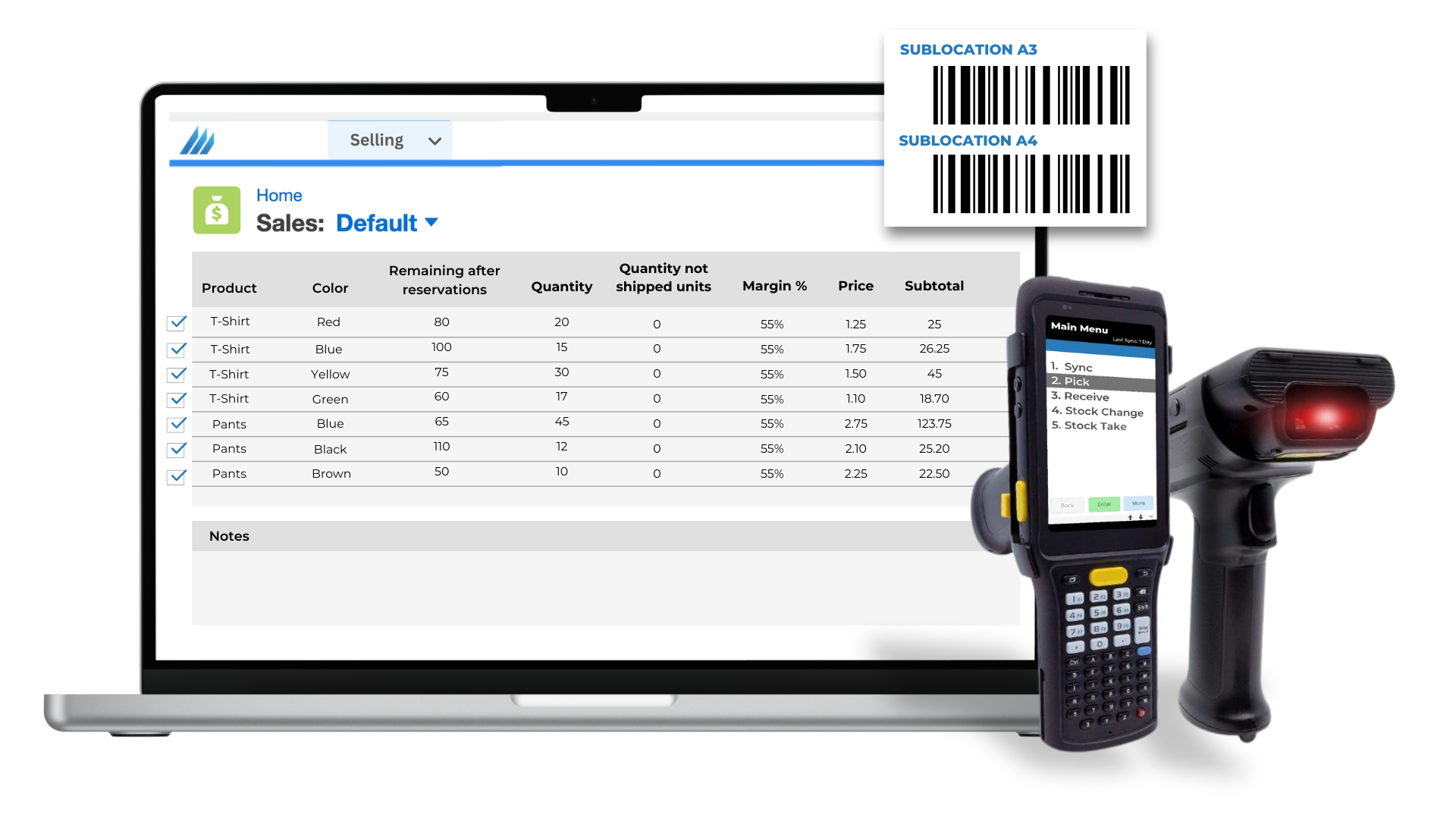

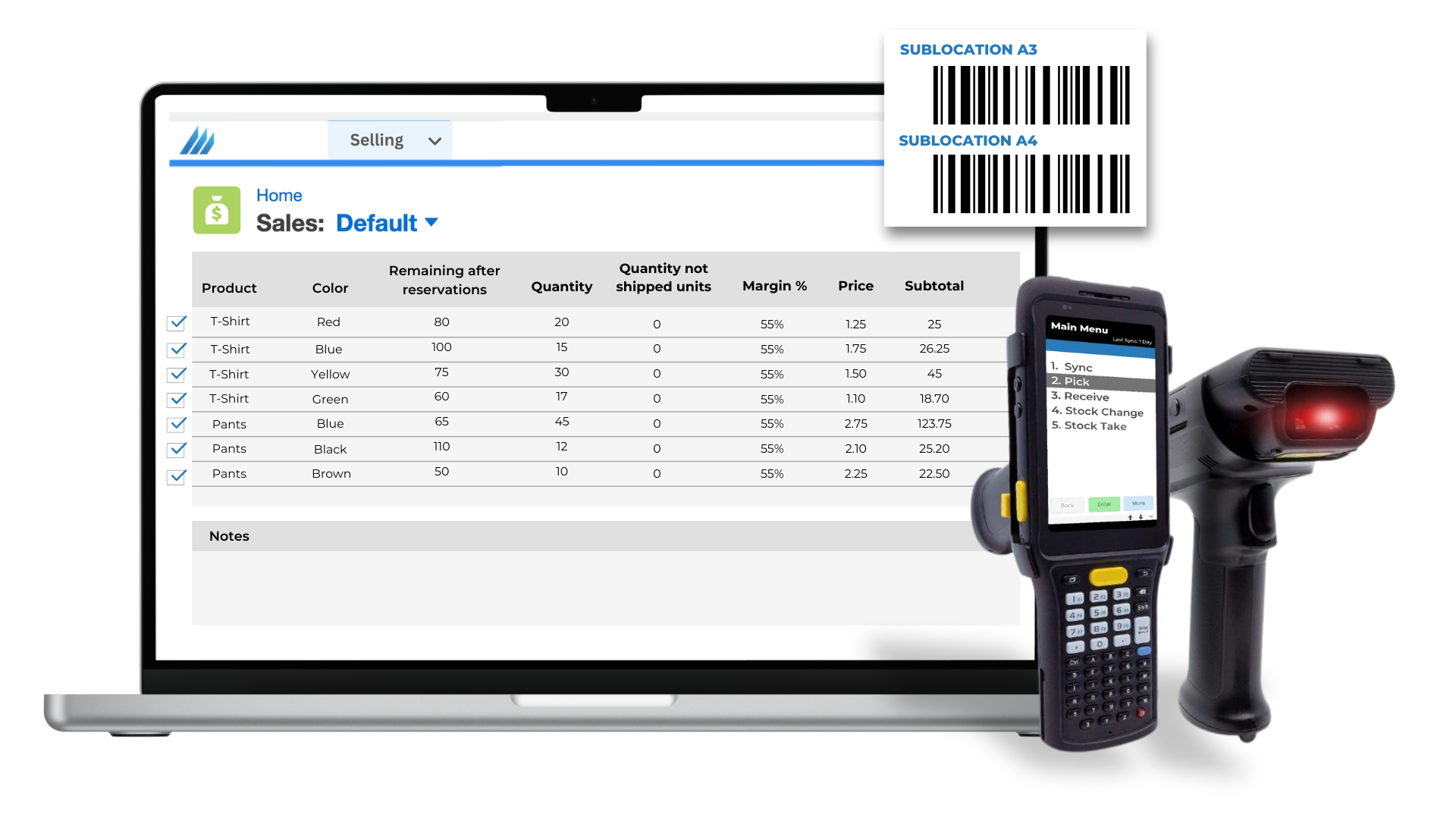

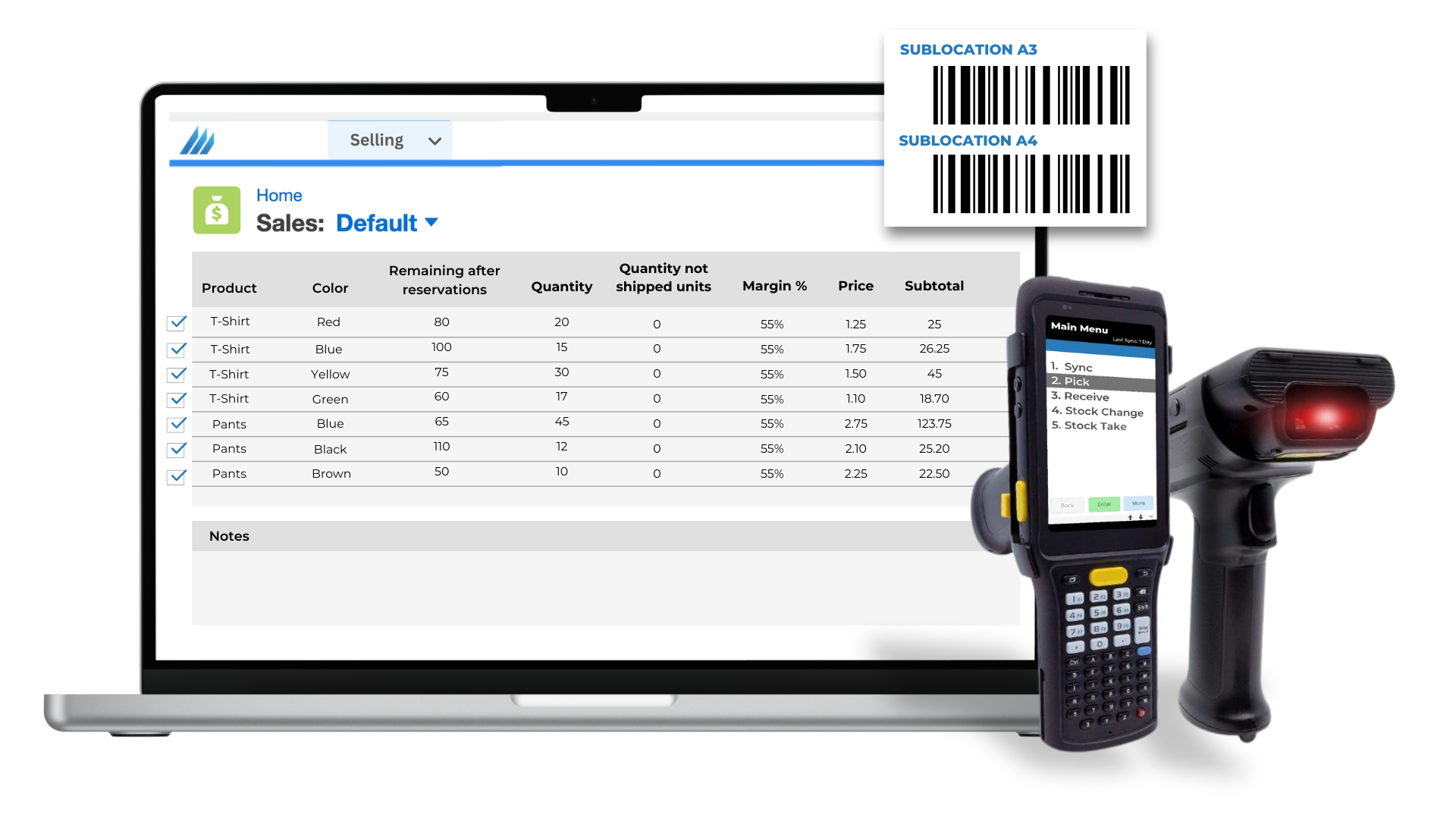

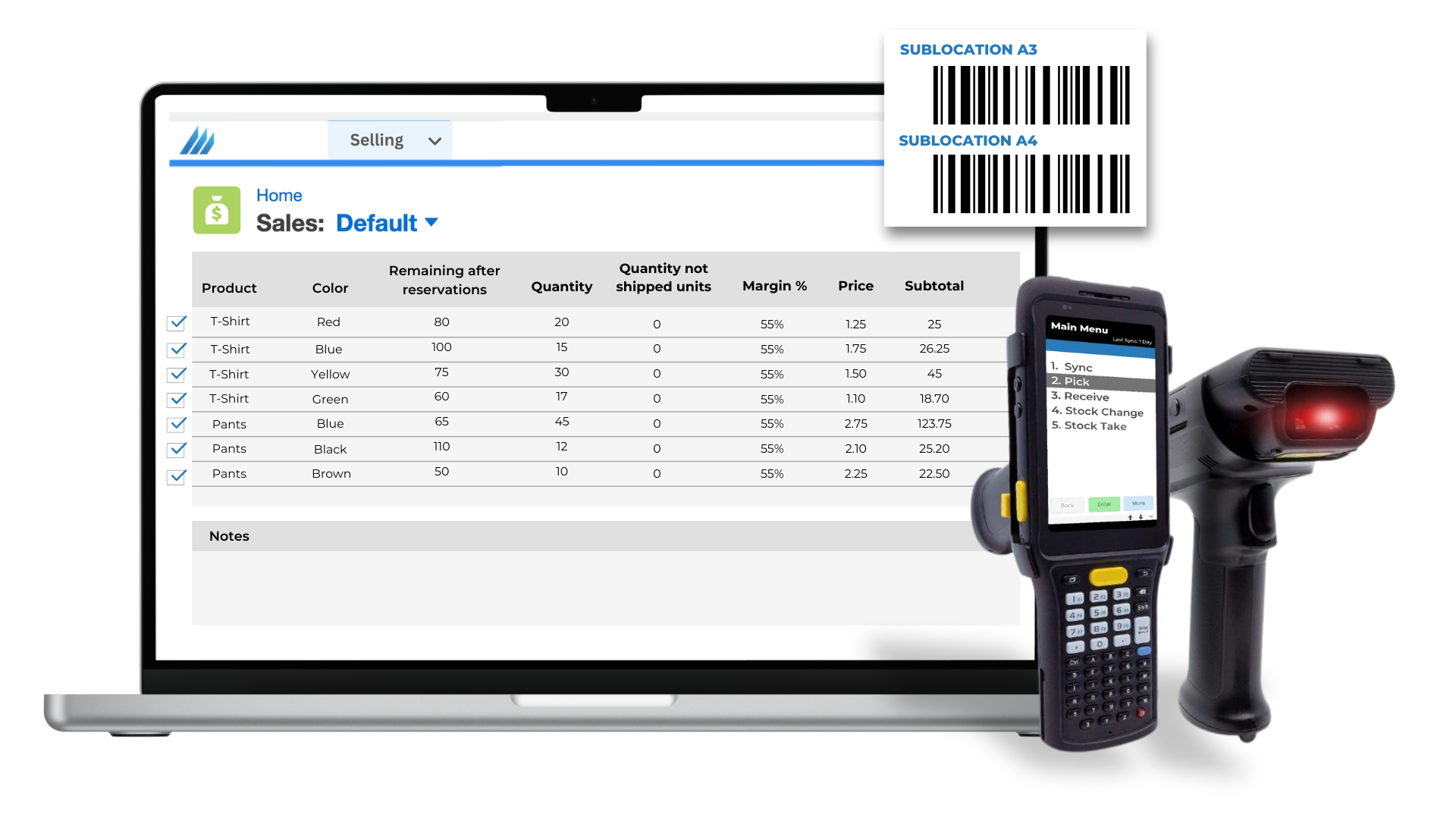

Basic Order Picking with a Mobile Barcode Scanner

Supercharge Your Warehouse Operations with Our Powerful yet Simple Barcode Scanning Solution

Using Finale Inventory's versatile barcode scanning system for order picking enhances accuracy and speed by instantly verifying items against orders, reducing errors and fulfillment time.

Improve Warehouse Accuracy & Efficiency with Basic Order Picking

When to Use Basic Order Picking

Finale Inventory's versatile barcode scanning system offers multiple fulfillment methods—Batch Picking and Basic Picking—empowering you to choose the best method for your workflows. Discrete picking involves fulfilling each order individually, one at a time.

- In some instances, basic order picking is the best option if the items are large oversized, high-volume orders, or complicated orders that need attention to detail.

- If the number of pickers working in a warehouse is small, it often makes sense to use a basic or discrete order picking method. This method allows a warehouse to assign each person a distinct order so multiple orders can be scanned and fulfilled concurrently.

Barcode Efficiency: Traceability, Cost Savings, and Scalability

Barcode systems enhance traceability and accountability by logging every scan to track who picked items and when maintaining detailed order histories, and linking serial numbers to specific products for warranty management. These features drive cost savings by reducing returns through accurate order fulfillment and optimizing labor by minimizing the need for error corrections or audits. Additionally, barcode solutions scale effortlessly to handle increasing order volumes, supporting multiple users simultaneously without sacrificing speed or accuracy.

Scanners direct pickers to the exact location of items with guided workflows (e.g., aisle, shelf, or bin), speeding up the picking process with near-instant updates to the central system after scanning so that stock levels are updated, saving time on manual stock adjustments.

Basic Order Picking for Wholesale

Basic order picking is better for wholesale orders because it focuses on fulfilling one order at a time, ensuring accuracy, and reducing errors when handling large quantities or high-value items typical in wholesale operations.

Basic Order Picking for Large Order Volumes

Basic order picking is ideal for large order volumes, such as selling by the pallet, because it allows workers to focus on fulfilling one order at a time, reducing errors, and ensuring that single-order bulk shipments are accurately prepared and efficiently moved to their destinations.

Basic Order Picking for Oversized Products

It can be challenging to place more than one oversized item in a cart simultaneously, so these types of orders are often best handled individually.

Basic Order Picking for Complex Orders

Basic order picking is ideal for complex orders, such as a phone order that includes different headphone, cable, and case options, because it allows the picker to focus on one order at a time, ensuring attention to detail. This method reduces the likelihood of errors in assembling multiple components and ensures that each part of the order is accurately picked, packed, and ready for shipment.

Finale Inventory. The Ultimate Basic Order Picking System.

Whether scaling operations or tightening processes, our system is your gateway to faster, smarter, and more reliable order fulfillment.

Discrepancy Alerts

Barcode scanners boost efficiency by enabling employees to adapt quickly with minimal training, thanks to their user-friendly interface, leading to faster order fulfillment. They also provide real-time inventory updates, ensuring accurate stock records and immediate alerts for discrepancies through audio and visual cues, helping resolve issues on the spot.

Enhanced Productivity with Real-Time Inventory Management

Barcode scanners boost efficiency by enabling employees to adapt quickly with minimal training, thanks to their user-friendly interface, leading to faster order fulfillment. They also provide real-time inventory updates, ensuring accurate stock records and immediate alerts for discrepancies through audio and visual cues, helping resolve issues on the spot.

Yes, if you already use Shipstation you can easily connect Finale Inventory with the powerful integration.

Yes, you can scan in shipments to your warehouse or retail location as part of your procurement workflow.

Yes, you can use easily sync transfer orders from Amazon Seller Central, then pick and pack shipments to get them sent to Amazon's fulfillment centers easily.

Yes, this system can generate unique labels. Learn more about scanning and labeling.

Use Finale's label printing solution.

There's more to printing labels for inventory than you might think. If your warehouse operations encounter issues with stocking, high costs, low efficiency or tracking errors, you may need to rethink your labeling system. Finale Inventory offers custom barcode label printing services that can integrate with inventory management software to give you up-to-date information about all your stock.

Yes, quickly conduct stock takes and stock counts with the handheld scanner. No more manual counting with clipboards and paper.