Wave Order Picking

Wave Order Picking Solution

In addition to single order picking and the pick and pack method, Finale Inventory provides support for wave picking. When implemented correctly in your facility, wave picking can improve productivity while keeping operating costs low – effectively helping you get more out of your team without compromising accuracy. To help you learn more, we’ll provide an overview of wave picking, its main benefits and some of the ways Finale Inventory can help you implement it in your warehouse packing procedures.

What Is Wave Picking?

The definition of wave picking is combining similar orders into a batch and pulling the inventory for all orders simultaneously. The idea is to reduce the number of picking trips required. These batches can be defined according to several factors — priority, shipping carrier, location and more, according to the needs of your operation.

As an example of wave picking leveraging a mobile barcode scanner, you could plan to pick all orders due to be shipped at a particular time using the same carrier all at once. Or, you could pull all the pending shipments that contain an SKU in a particular zone of the warehouse. Both of these strategies can improve operational efficiency for a warehouse, depending on your business needs. Some warehouses enhance wave picking by scheduling them precisely to ensure on-time fulfillment.

When you have a high volume of orders coming in, wave picking is an excellent way to increase productivity. However, to ensure accuracy and that no products are forgotten, sophisticated wave picking software is needed, which is where Finale Inventory comes in.

Get Started with Finale Inventory Today

However you organize your warehouse, Finale Inventory is an essential tool. To learn more about wave picking with our product, contact us or sign up for a free trial today!

How Does Wave Picking Work?

Finale Inventory's mobile barcode scanner makes it easy to pick and pack multiple orders in a single trip to the warehouse. With our Android barcode app, you can create consolidated lists for order pickers that identify how many of a given SKU are required. Then, using the directed picking capability on the scanner, your team can pick individual items and pack them in sequence, rather than proceeding one order at a time.

The scanner helps ensure order accuracy by providing an audio and visual confirmation when the correct product is scanned or a warning buzz and accompanying message when the wrong product is scanned. It then prompts the next item required until the completed order is ready to go.

Once you batch the orders, you'll then need to enter the wave picking process. Here, you typically assign each order to a corresponding tote or bin, as shown below. The scanner app keeps track of specifically which tote or bin the order belongs to, and as you're pulling inventory, the scanner will prompt you to place the items into the corresponding slots for the orders that require them.

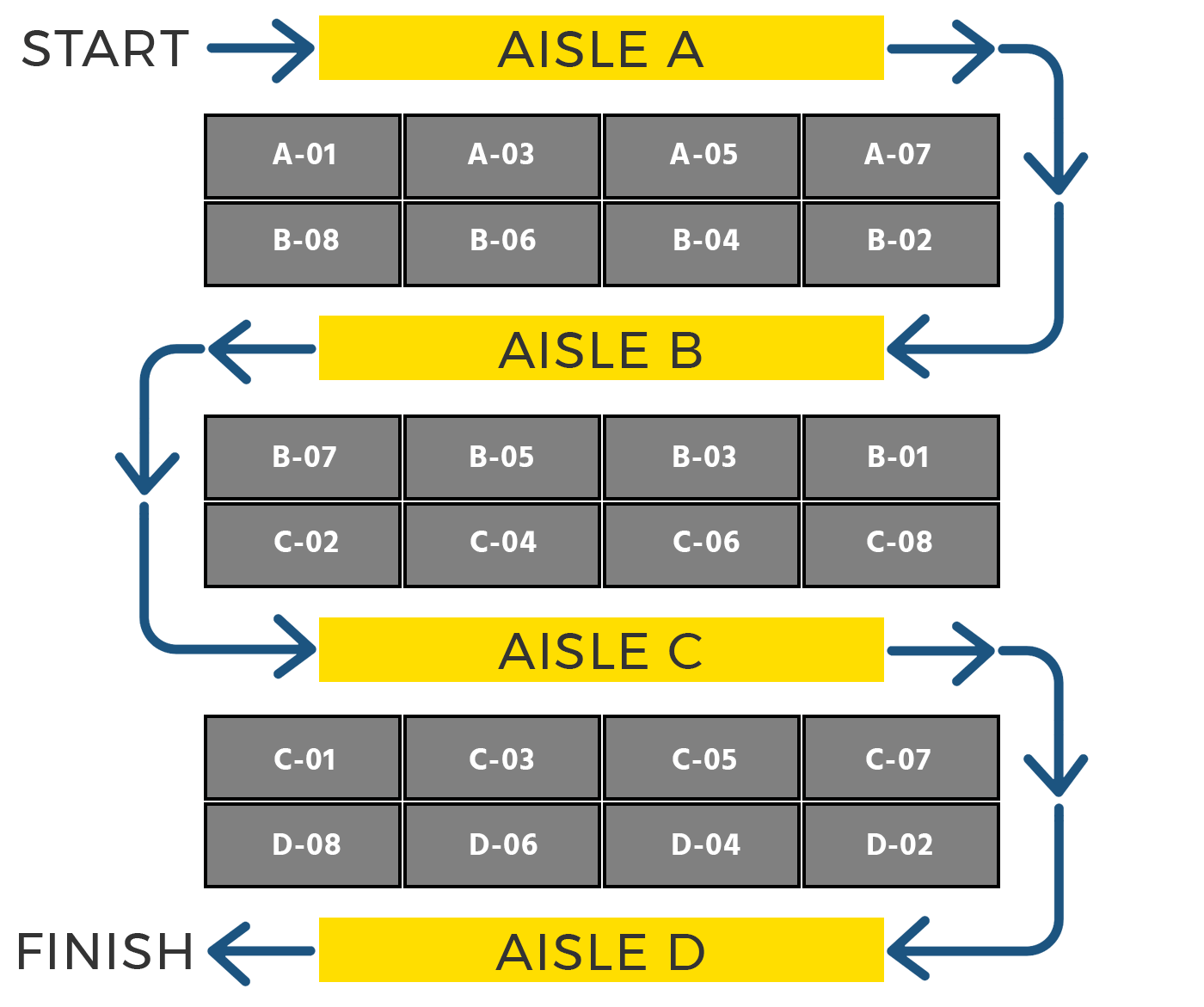

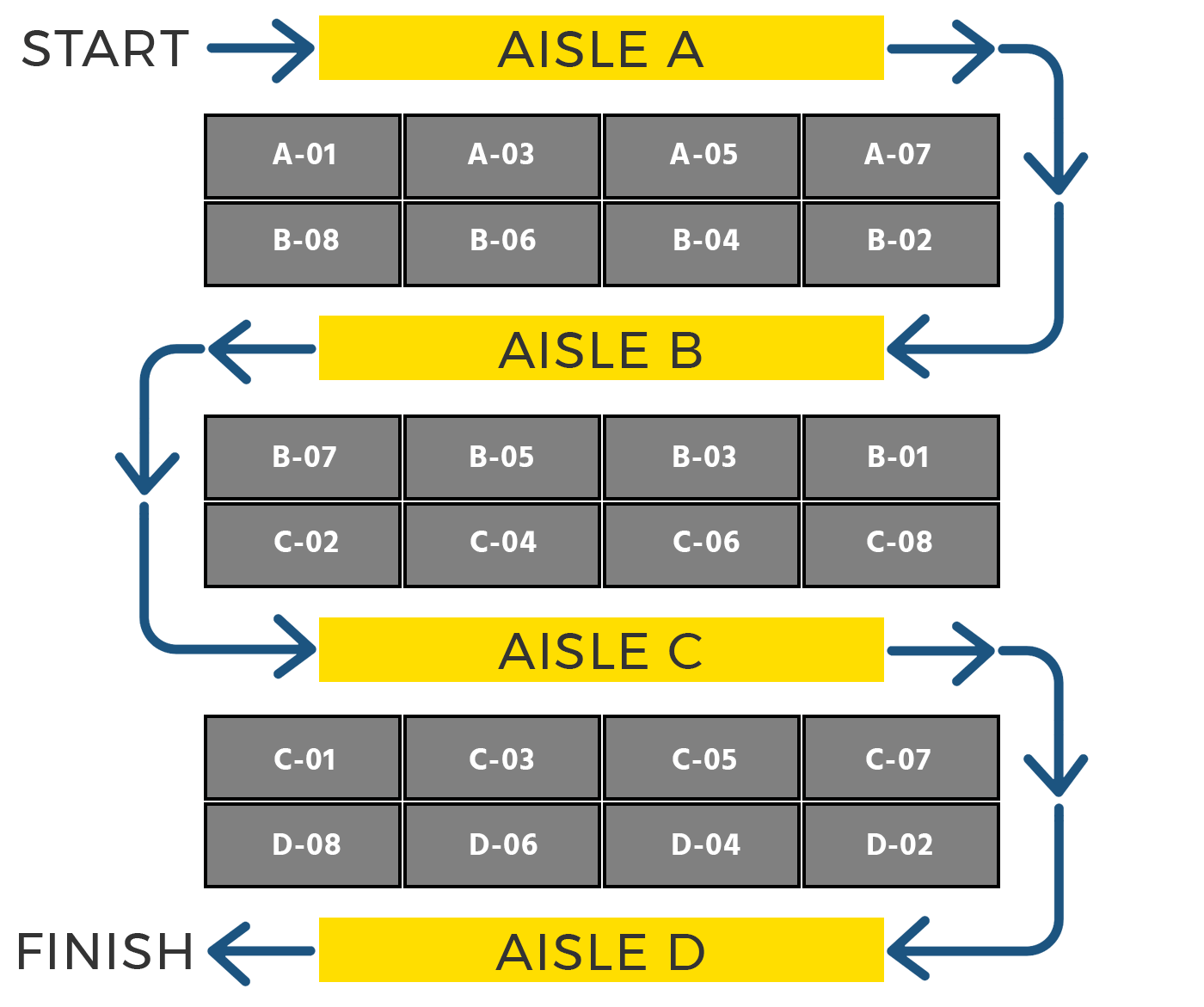

Once you've assigned all of your orders to totes or bins, you can begin pulling the inventory. Here is where Finale Inventory's mobile barcode scanner will direct the picker through the warehouse. Usually, the software will go in alphanumerical order of sublocation — see the example below.

As you go through the warehouse, you'll fulfill each order, so by the time you reach the end of the warehouse, all of the orders in the batch will be fully picked and packed. The only step left would be to physically package the orders with shipping labels.

Check out the video below to learn more about Finale wave picking and batch order picking solution.

Benefits of Wave Picking Order Fulfillment

The main advantage of wave packing is its ability to reduce the travel time through the warehouse. Consolidating picks according to specific qualitative and quantitative criteria lets your team process them in the manner that makes the most sense rather than as they come in.

Wave inventory tracking and order picking aren't right for every business. Typically it yields the most benefits for medium-to-high-volume operations with a low number of SKUs - or operations where orders with the same SKUs are common. The top advantages of the wave picking method include:

During the order picking process, warehouses can lose money through either motion waste or waiting waste. Curbing motion waste is particularly important because 60%-70% of a warehouse worker’s time is spent walking from one location to the next. Wave picking can reduce motion waste significantly because workers can pick several orders in one trip through the warehouse. Instead of taking a different route for each order, the worker takes one path through every product location relevant to the current wave of orders.

Wave picking can also reduce waiting waste because each wave is precisely scheduled. You can schedule pickers for each wave based on other operations, such as when the delivery truck will arrive for pickup. Wave picking provides a tight schedule for which orders need to be picked and when reducing time spent waiting.

How Finale Inventory Can Help You Increase Efficiency

While wave picking can be the right choice for many businesses, it's not ideal for every company. Finale Inventory works closely with each client to find solutions that work best for their business. We can help you determine whether or not wave picking is the right choice for your warehouse and configure a management system that does it effectively. We support wave picking, the pick-and-pack method and discrete picking to help all businesses pick their orders most efficiently. Our platform is scalable, fast and flexible enough to accommodate multiple management methods.

Wave picking requires a barcode inventory management solution to keep track of the many orders being fulfilled at once. Finale Inventory's barcode scanning application tells pickers which items to grab and which order each item belongs to. When you arrive at the location for a product in multiple orders, the barcode scanner will tell you how many to grab and which slot in the cart to deposit them into.

When you use Finale Inventory's barcode solution for wave picking in your warehouse, you benefit from:

- Efficient routes through the warehouse: If you organize your warehouse sublocations in alphabetical and numerical order, Finale Inventory will automatically direct workers in the fastest path through the warehouse. Workers won't waste time traveling back and forth through the warehouse while picking for the same wave.

- Faster, more accurate picks: The barcode scanner also tells workers exactly what items to pull and which slot to put them into. When a worker makes the wrong selection, an instant notification alerts them to the error. This reduces picking errors and allows workers to fill orders quickly without taking frequent breaks to read over the picklist.

Potential drawbacks to wave inventory picking include the possibility of fulfillment delays when working with a high number of SKUs. In some cases, it may also lead to unacceptable levels of idle time for order pickers. Wave picking can also be a problem when you're dealing with heavy or bulky items that are difficult to transport together in a single trip.