How To Manage Inventory Effectively With These 3 Proven Tips

What Is Inventory Management?

Inventory management is a component of supply chain management that involves tracking how your goods enter and leave the warehouse. A well-formed inventory management strategy allows you to keep up with how much stock you have on hand, how much you need to order, what dates your merchandise ship on, and much more. Managing inventory is integral to the foundation of any product-based business. Without it, operations could not succeed.

By practicing successful inventory management, you gain detailed insight into the most minute operations of your business. You won’t have to stress about overstocking goods or miscalculating stock amounts when you have a firm grasp on every aspect of your warehouse.

Here are a few details you’ll become familiar with as you learn more about managing your inventory:

- Stock transfers

- Product landed Cost

- Product quantities

- Lot IDs

- Sales trends

- Supplier lead times

- Economic order quantities (EOQ)

This overarching business technique is fundamental for product-based industries, but each company handles it differently. Some of the factors listed above may become more vital than others, depending on what you manufacture and ship. Understanding these nuances — and the particular needs of your business — will help you get the most benefits from tracking your inventory.

Why Is Inventory Management Important?

Inventory management is essential for helping your company grow and thrive. Too often, a business runs into ruin and failure because of small errors like poor inventory management that they could have easily avoided. The most unfortunate thing is that if you don’t put these proven tips and practices into place from the start, it can be incredibly difficult to remedy any mistakes that may come from doing business without them.

For example, holding inventory for too long can halt the flow of money. Stunted money flow can destroy your business, giving you little hope to build it up again. Products that don’t move off the shelves occupy precious space and can leave you with limited room for the rest of your goods. Alternately, picking and packing the wrong orders can result in unhappy customers. These buyers may then leave unpleasant reviews about your company, which hurts your reputation.

Many companies still power their supply chains using manual labor, which can increase the risk of error regarding inventory checks. Recording an inaccurate quantity can lead to a business ordering more supplies when it’s not necessary, costing them time and money. Similarly, a company may postpone re-ordering because they think they have enough of an item, but it’s actually out of stock. Human mistakes are unavoidable and can cost you substantially over time.

Issues of miscalculated quantities aren’t always due to simple mistakes — sometimes, they occur because of employee theft. If you have a clear and accessible way to look back on your stock history reports, you’ll locate discrepancies more quickly. You can draw informed conclusions about whether inconsistencies are due to simple inattention or intentional dishonesty. Fortunately, our three proven tips can boost your business smarts and put you ahead of the game, ensuring success and proper business management overall.

Handle Stocks Effectively With These 3 Inventory Management Techniques

There are many approaches to managing inventory, and some strategies work better than others for some businesses. As your company grows, you’ll learn which techniques are right for you. However, these three proven tips are excellent for organizations of any size. If you want to know how to manage inventory effectively, make these methods your starting points:

1. Employ ABC Analysis

ABC analysis is a good place to start when it comes to learning how to manage inventory effectively. This analysis system is simple to learn and understand, and it streamlines your inventory into a configuration that is both easy to manage and maintain. ABC analysis works by arranging all the items in your inventory into a hierarchy of least important to most important. When put in practice, ABC analysis looks something like this:

- A-items: These are your high priority, best-selling stock items that call for regular re-ordering and quality review. If these items are not often stocked, shipped, and replenished, it could result in poor customer service, loss of business, and even loss of money. To identify A-items, investigate what is popular, what leaves the shelf first, and what customers are always asking after.

- B-items: These items are valuable but less so than A-items. They are medium-priority stock and usually call for monthly re-orders. Though they are not as popular as A-items, their absence or a delay in their replenishment does not go unnoticed.

- C-items: These items are low-priority stock and are often carried in high volume. They do not move from shelves as quickly or as often as A- or B-items, meaning you usually have more despite less demand. They require minimal re-ordering and may require smaller amounts when ordering to save on costs over time.

When you organize your stock by this standard, you actively streamline your inventory so that the way items sell directly correlates to what is more popular and in higher demand. In time, this technique can optimize your storage space as well as modernize your order fulfillment. You may combine this method with other strategies to create an even more efficient business system. Once you identify the A-, B-, and C-items in your stock, you can use FIFO to arrange them by oldest to newest merchandise. Therefore, your customers will always receive the freshest possible products, without the wear-and-tear that often comes with letting goods sit for too long. This management method is especially vital for those who sell perishable products. Wares that become dead stock chip away at your profit and available warehouse space.

2. Use a Cloud-Based Inventory Management System With Barcode Scanning

One of the best strategies for effective inventory management is to start using a cloud-based inventory management software system. It’s even better if your system comes with barcode scanning. Cloud-based inventory management systems allow businesses to pay for excellent and necessary features that they can upgrade when needed as their company grows. What’s more, a software system with barcode scanning offers a certain level of accuracy that is not easily attainable when managing inventory manually.

You enjoy numerous perks when using cloud-enabled barcode scanning:

- Easier shipments: Shipping becomes smoother on both ends when you can record your product data and trace orders from beginning to end. If incidents occur while sending out goods, you and your customers can benefit from a detailed stock history report. Showing that you’re responsible with handling your merchandise makes you more trustworthy to current and potential buyers.

- Faster stock transfers: Initiate and record stock transfers with your barcode scanner and never miss out on documenting another shipment again. If your business spans multiple locations, expediting this feature is crucial to meeting administrative duties and ensuring products arrive at the correct warehouses. Enter your stock transfer, and it’ll immediately go into the cloud, accessible for all workers who manage this task.

- More accurate picking: Scan all your orders into the system with your barcode scanner, and they’ll automatically update to show their new status. A precise order picking solution prevents costly inaccuracies, and precision is essential to this stage of fulfillment. Picking and packing the right items every time enhances customer satisfaction and reduces your number of returns.

Most cloud-based systems are obtained by paying a single subscription fee that renews monthly or yearly. Finale Inventory works on a month-to-month basis for low commitment — no need to devote yourself to a six- or 12-month plan. Cloud-based programs include certain features, like auto purchasing and replenishment of popular products, multi-warehouse data and management, Lot ID tracking, serial number tracking, barcode inventory solutions, and much more.

Many programs also allow for integration with other applications, meaning you can handle inventory accounting, shipping details, and point-of-sale systems all in one location. In short, a cloud-based inventory management software system will remove all the headaches from inventory management. A high-quality software system can make inventory data simple, quick, and easily accessible from any location and device, whether it is your phone, laptop, or tablet. The system also automatically backs up all your data so nothing is lost, and software updates ensure you always have the latest version ready to go. Additionally, you don’t have to worry about IT costs when you’re working with your own database system. Using a personalized program gives you greater control over your business, allowing you to troubleshoot inventory issues and make changes to your software parameters without going through multiple parties.

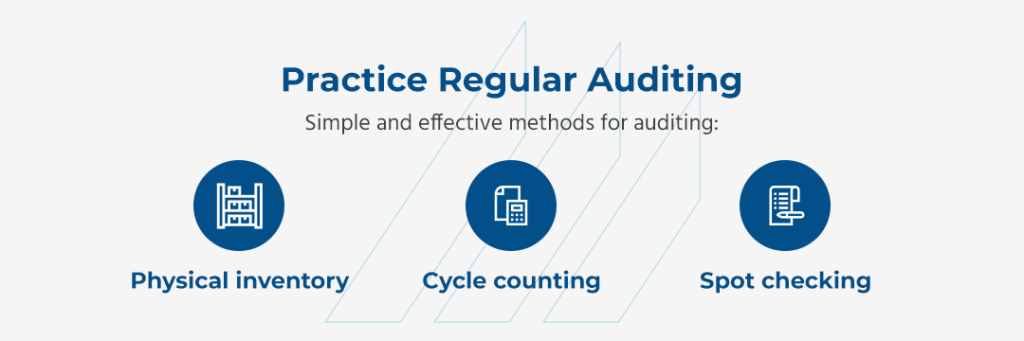

3. Practice Regular Auditing

Auditing is one of the best ways to ensure that inventory and numbers match up. Whether you are working with a software system or handling the numbers yourself, you should always double- and triple-check things to ensure that inventory stock and recorded figures are on point. If they aren’t, this could signify lost items, miscalculations, or misplaced money, which could lead to other issues. You have a few simple and effective methods for auditing:

- Physical inventory: A physical inventory audit means you count all your inventory at one time. Most companies using this method count their inventory when the fiscal year ends, tying this even to accounting and income tax processes. Of course, a physical inventory audit can be time-consuming, tedious, and prone to mistakes.

- Cycle counting: An alternative to doing a complete physical inventory audit is to use cycle counting. With this method, companies never have to count all their inventory at once because they count in cycles during the year. You can do cycle counting by auditing a different product regularly, whether daily, weekly, or monthly, to make sure you don’t miss anything. You determine how often the cycles come around so that you have a system that works best for your specific business and products.

Spot checking: Spot checking pairs well with a full physical inventory audit once per year. To mitigate issues with physical inventory, you can spot-check throughout the year. It’s effortless and only involves selecting one particular product, counting it, and comparing this number to the product quantity in your records. You don’t have to do it on a schedule — it’s most useful as a supplemental activity to physical inventory. The best products to spot check are those in high demand with customers.

How Inventory Management Can Save You Money

Adopting a system for inventory management can save you significant amounts of money on business operations. According to a study from IHL Group, the retail industry loses $472 billion a year to overstock. Inventory distortion generates a price tag of $1.1 trillion, accounting for 7.3% of global retail sales. With stock-outs and overstocks constituting over a trillion dollars in the economy, it’s clear to see that improper inventory management can cost you substantially.

Every decision counts when you have expectant buyers and products to sell. If an entrepreneur runs a brick-and-mortar store and experiences a stock-out, their customers are more likely to turn to e-commerce or a local competitor instead of waiting for their store to restock. Although this money stays within the industry, it counts as a loss for that business. However, as an e-commerce store owner, these kinds of situations can benefit you.

In the worst-case scenario, continually losing money to inefficient processes can lead to difficulty restocking because you lack the funds to buy more goods. When you understock, you’ll end up paying higher shipping costs because of frequent re-ordering. These problems compound, which is why it’s essential to set up a practical inventory strategy from the start. Your stocks directly affect your cash flow. By streamlining your warehousing methods, you bring your business closer to increasing its revenue and procuring a higher number of satisfied customers.

Common Inventory Management Questions

Like with any new business process, you may have a range of questions concerning how to handle inventory effectively. Below are some commonly asked questions about inventory management, which can help you determine the next steps to take.

How Do You Know If You Need a New Inventory Management Strategy?

You’ll notice many distinctive signs when it becomes apparent that a new system for inventory management is necessary. Your business may be growing, which could mean extending your product line or opening new locations. You may find it increasingly difficult to handle your inventory, leading to higher instances of miscommunication, inaccurate picks, or stock-outs. Maybe your money flow isn’t as tight as it could be, and you need insight into how inventory is moving.

Or, maybe you aren’t experiencing problems but would like to add a new feature to the supply chain, such as in-store pickup or mobile capabilities to your current software. If your strategy doesn’t support the adoption of such crucial advancements, it’s time to develop another. Whether your concerns are major or small, it’s worth considering some improved techniques if you recognize areas of improvement within your operations.

How Do Spreadsheets Compare to Inventory Management Software?

Spreadsheets are the primary platforms for businesses that still handle their inventories manually. Companies that use spreadsheets are more likely to be small to medium-sized, as they don’t yet have a pressing need for more sophisticated systems. However, spreadsheets can still be time-consuming and ineffective compared to cloud-based systems.

With an inventory management software solution such as Finale Inventory, you can implement new ways to handle actions like these:

- Serial number tracking: Serial numbers are a necessity for many businesses that sell variations of similar products. However, tracking serial numbers isn’t always easy for paper-based systems. You may have better luck turning to software to handle these intricate codes. By using an application, you can be certain that the products you send out are accurate and will reach their intended destination.

- Location expansion: If your company grows and adds new locations, you’ll need to upgrade your capabilities to match the additional warehouses and stock quantities. A cloud-based system allows everyone to access the appropriate data from their tablet or computer without wasting time with paper documents.

- Data centralization: It is much more convenient for workers to log onto a company-wide cloud system than send paper spreadsheets back and forth, at risk of mixing up documents. Forgetting even one sheet can drastically alter your stock reports, ending up with everyone on a different page.

Additionally, software solutions are becoming attractive in an increasingly technological world. When the difference between speed and accuracy can mean falling behind or shooting ahead of competitors, a tech-based answer can eliminate your worries.

Does Inventory Management Work for All Inventory Types?

Whether you stock raw materials or finished products, you need an effective way to manage inventory to be successful. Each type of inventory will require different techniques, but they all need an organized structure. Your cost of goods sold and other expenses will decrease if you practice smart management, which is favorable no matter what type of company you run.

Practice using the EOQ formula to reduce the costs of ordering new raw materials. Use the days inventory outstanding (DIO) equation to help you develop ways to move finished products off the shelves faster. Streamline your manufacturing methods to decrease the quantities of work-in-progress inventory occupying space in your facilities. If industry regulations call for specific documentation of every item — whether it’s pharmaceuticals or fireworks — inventory management can keep you in compliance.

How Can You Measure Successful Integration of an Inventory Management System?

Successful integration hinges on a few common goals, although your definition of success will depend on your company’s specifics. The main objectives of any inventory management system are to increase replenishment efficiency, provide a comprehensive view of stocks, allow for quick scalability, and lower inventory-related costs. To determine if a new solution is working as intended, you must investigate past data and compare it to your current numbers.

You may ask yourself questions such as these:

- How much has your dead stock decreased since adopting new techniques?

- Have occurrences of stock-outs and overstocks decreased?

- Without the need for manual counting, has there been an increase in how much time employees have for other assignments?

- Have your warehousing costs dropped, whether incrementally or significantly?

Manage Your Inventory Effectively With Finale Inventory

Learning how to manage inventory effectively will get easier when you implement these three proven tips. These show that small changes can make a big difference in the life of your business. When it comes down to it, your company needs customers, consistency, and proper management to survive.

Take your management strategies to the next level by signing up for a free trial of Finale Inventory’s inventory control software system. Our software solution will help you scale up your e-commerce business and gain detailed knowledge of your stock while meeting your specific operational needs. Store all your data in our secure cloud-based system, and you’ll have everything you need for a successful company at your fingertips.