Regardless of the process, every manufacturer, supplier, wholesaler, retailer and business needs a way to keep their inventory in check. Without a well-defined system, any business will suffer confusion, delays and errors during daily operations.

Serial numbers provide an excellent method for organization. In conjunction with inventory tracking software, your company has the opportunity to set a new standard of efficiency and have the benefit of fewer mistakes and less time spent correcting them.

If you need an inventory management tool, look no further than the serial code system. This guide to serial number inventory tracking will provide you with everything you need to know to implement it in your business.

- What Is Serial Number Inventory Tracking?

- What is a Serial Number?

- What Does a Serial Number Tell You?

- How Does the Number System Work?

- What Are the Benefits of Serial Number Inventory Tracking?

- Who Should Use Serial Number Inventory Tracking

- How to Track Serial Numbers Effectively

- Why Use Serial Number Tracking?

- How to Get Started

What Is Serial Number Inventory Tracking?

Organizing and accounting for an entire inventory of items is difficult work, and having a complicated system in place can result in inefficiency and errors. Serial numbers are helpful to businesses looking for a thorough method of organization to apply to their stock.

What is a Serial Number?

A serial number, also sometimes referred to as a serial code, is a string of letters and numbers assigned to a particular product or element of a product. It is placed somewhere on the item physically, usually preceded by “SN” or “S/N” to differentiate it from model numbers and other identifying codes. Each number is unique so every item may be identified by its assigned code.

When used in warehouses and for business purposes, serial numbers keep track of individual units, rather than lots of shipments or production batches. Items organized into lots will share the same number or identification code. Serial numbers are never shared. Instead, they are individually assigned to single items and are never repeated, acting similarly to a fingerprint.

For example, almost all electronic devices — including phones, tablets, laptops and routers — and their hardware components have serial numbers that differentiate them from other copies of the same models. Electronic manufactures also use serial numbers to track warranty claims for a specific unit. Manufacturers and retailers can use the serial code to log each device in an inventory and keep track of its whereabouts. You can usually find a device’s number on the exterior.

What Does a Serial Number Tell You?

By assigning and using these codes, manufacturers and retailers can track individual items throughout the entire process of purchasing, storage, production, sale, distribution and post-sale customer support, such as warranty claims, refunds and returns. Any identifying factors can determine the numbers and letters, but they cannot be the same as any other code previously used.

Using serial numbers as a system to create an easily sortable inventory makes management far simpler and more efficient — especially in cases where a retailer or warehouse is storing and shipping hundreds of similar units at once.

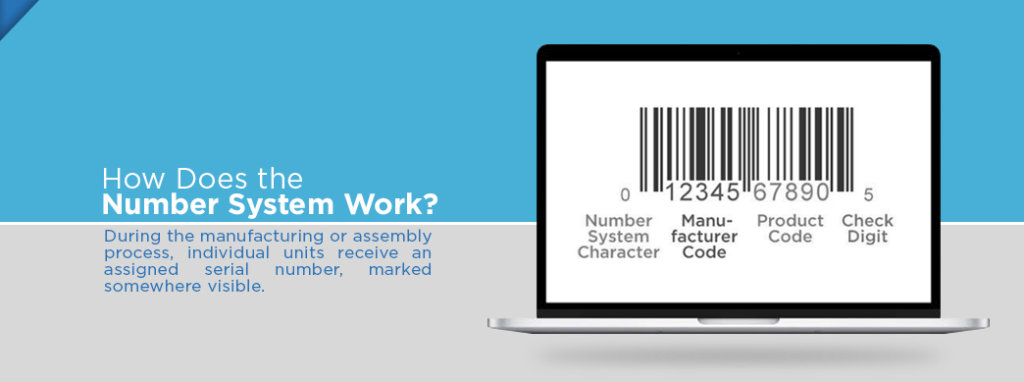

How Does the Number System Work?

During the manufacturing or assembly process, individual units receive an assigned serial number, marked somewhere visible. When the item is stored, the number is inputted into a spreadsheet or organized list. If the units move anywhere or are being prepared for shipping, the number is logged as such, keeping track of the movements each unit makes.

Since the process is dependent on how the items are stored and move, the specific organization of it can be individualized to meet the needs of any company. However, the general principle and guidelines remain the same.

The first step is always assigning the numbers — they should be attached to individual items at the time they are manufactured or delivered to warehouses by suppliers, to ensure every unit receives one. As they are assigned, the codes need to be recorded to keep track of what is included in the large stocks and shipments.

Once an inventory specialist has logged every item with a mobile barcode scanner, businesses can create a workflow based on the system put in place. If organized well and documented correctly, each item will be tracked throughout its journey, leaving a comprehensive log of everywhere it has been. This includes dates and locations from the time the manufacturer ships it out to when the customer receives their purchase.

Customers are included in the database and paired with the serial numbers of the products they have ordered or bought. This way, should they need to return the product, request a refund or need to take advantage of the warranty, retailers can confirm that it is the same product, using the serial number. They can also issue specified recalls, if necessary, following customer complaints.

In terms of labeling the units, some companies choose to print stickers with the codes, affix them to the items and track them using a spreadsheet. It’s relatively cost-effective but leaves a lot of room for errors, inaccuracies and inconsistencies, potentially losing them money.

The better alternative is to invest in a software system that allows for easy documentation and tracking. With an organized program on your side, you’ll benefit from less confusion and room for error.

Solutions like Finale Inventory will provide you with a custom fit program, tailored to your industry and the way your business operates. Our software makes documenting warehouse inventory, managing purchases and tracking sales run smoothly, no matter the company.

What Are the Benefits of Serial Number Inventory Tracking?

Organization is key to running any operation smoothly, but some methods will bring more to your company than just clean documentation. Managing your inventory by way of assigning serial codes is a move that will bring many added benefits to your business.

Along with keeping organized, you can:

- Boost efficiency: For one, you’ll see a higher level of efficiency, as each item is easy to locate and track down. The visible organization allows you to improve workflow processes. No more being held back by difficulties or delays.

- Easily track items: The documentation will allow you and your suppliers or clients to trace any single item back to the point of its manufacturing. If any product or close group of products has issues, the manufacturer can check to see if a production error is the cause or if it’s on the customer.

- Provide better customer service: Your company can handle and investigate warranty claims easily, and either issue a trade, return, refund or send out a full recall, should the problem stem from improper manufacturing or production faults. Also, you can provide your customers with specific details about their model, based on the serial code.

- Prevent fraud: You’ll be able to ensure that a returned item is the same product you sent, simply by checking if the serial number is the same.

- Identify popular products: Tracking the serial numbers of sold items can provide you with a list of your most popular sellers — this will allow you to make informed restocking decisions when the time comes.

- Reduce the risk of error: When working with heavily regulated businesses and products, making a shipping error can be a huge mistake. But, with correctly organized serial numeration, you’ll avoid the risk.

- Analyze sales: Each sale and shipment will provide you with information about your business, top customers and remaining stock. With an organized system, you can easily view these statistics at any time.

Other traditional methods of organization don’t allow for nearly as many benefits. Having a unique number assigned to every individual product that you store and ship will provide your company with far more advantages and a smaller margin for error.

Serial codes are a smart way to stay organized and provide consistent access to the information you need to improve your business. But, before you begin to use this method, getting the right software to manage your inventory is essential.

Who Should Use Serial Number Inventory Tracking?

For many highly-regulated industries and products, serial numbering all inventory may be legally required and mandated, for the sake of ensuring correct materials and shipments. If it’s a requirement for your business, then your primary focus should be the software you choose to log your items.

If it isn’t required, then you should still consider using it as your method of organization. Serial numbers work well for any business that:

- Has a high-volume inventory: Any company that has a high-volume inventory needs to have a surefire method of logging and tracking all of their products. Otherwise, their business may suffer from disorganization and inefficiency. Most of them likely already use serial numbers to track their items. If your company deals with a large stock, using serial codes is the most effective way to ensure you can keep everything well organized.

- Has a smaller inventory: Serial number tracking is also perfect for businesses with fewer stock but are high ticket items. They provide accuracy down to the single product scale and ensure your shipments always go to the right place. With more benefits than just managing an inventory, your business will operate more efficiently all around, regardless of stock size.

- Wants to provide top-notch customer service: By using individualized serial numbers, you can track shipping, handle any item-specific questions or concerns, and provide your customers with a complete history of the item’s whereabouts. They can help you provide better customer service and support in the case of a warranty claim, or even help you prevent fraud. With the best service available, you can keep customers happy while also ensuring your company’s reliability.

- Sells custom products: Using serial numbers is also great for managing customized or made-to-order products, where not every model is the same. Sending the wrong model could mean losing business. With serial codes, you can effectively keep track of each custom item and be sure every order ships to the correct address.

- Needs a better method: Maybe your current organization style is just lacking or doesn’t work as efficiently as you’d like. You can improve it significantly by implementing the use of serial numbers, guaranteeing you more opportunity for tracking individual items and being sure of your inventory.

Serial number inventory tracking is an excellent organization option for any type of business, large or small, in any industry. And since this method is customizable, every company has the opportunity to use it.

Whether your business deals with sensitive or highly-regulated products or just needs a better system in place, you should be using serial numbers and tracking software to improve your inventory organization.

How to Track Serial Numbers Effectively

Once you decide to put a serial number system in place, you also need to implement an effective way to keep track of each numbered item.

Half of the battle is establishing a cohesive workflow and enforcing it daily. If items aren’t logged in the same order as the process, steps and numbers can get confused. Your company should be able to keep a clear history and track the location of any item from the time it reaches the inventory to the time it is delivered to a customer.

If you provide any customization or in-house assembly of different pieces, you need to keep track of where each piece is within the workflow and production process. Tracking throughout the process keeps your workflow efficient and provides you with valuable data about how your business operates.

You can use the collected data to monitor speed and effectiveness or to inform any potential changes you may make to the steps of the process itself.

There are also some pieces of equipment strongly recommended to help with tracking — namely, a label printer and barcode scanners. Barcode labels need to be easy to read and scan, so suitable printers are vital. Mobile barcode scanners allow you to track every code and check every shipment, logging and processing items with the ease of a handheld device.

Recording serial numbers without a barcode scanner is technically possible, but it is not recommended. Recording serial numbers consisting of a long string of letters and number will be prone to human error. Leveraging mobile scanners to scan the serial number from the barcode label will dramatically mitigate recording errors. While computers aren’t perfect, they are exponentially more accurate than any human ever could be for this scenario.

But with so much riding on organization, the method you use to log all of this data matters more than anything. The most effective way to ensure peak efficiency throughout every step is by way of reliable tracking software.

Using computer software will make it easy for you to record and keep track of items as they are delivered and shipped, while also providing you with easy access to data and statistics about your sales.

If you’re not familiar with how serial number tracking software works, or know you’ll need a refresher, find a company that will provide you with personalized support and a variety of resources. The more help you have, the easier it will be to transition into using a serial numbering system.

The software will be most useful if you customize it to the way you run your company so you can continue operations without interruption. Customization also ensures that your system is the best possible option for your specific business type.

All of this will help you use serial number tracking effectively and with little to no stress.

Why Use Serial Number Tracking?

Serial number tracking can bring a new level of efficiency and organization to your business. It is the most effective and accurate method of organizing any inventory, providing you with precise identification and data.

Importance of Using Serial Numbers

While some industries are legally required to use serial codes, such as vehicle component manufacturers and medical device manufacturers, those that aren’t should still consider adopting the same practices.

In addition to the benefits of using a serial code system, you’ll be making business easier on you and your employees. With less room for errors, workers can complete orders with confidence and in a shorter amount of time. Being free from the stress of uncertainty and mistakes will allow for better morale.

Serial number tracking makes stocking and shipping less of a hassle and saves time. Simplifying your processes and consistently tracking items means you’ll always know where to find what you need and confirm it as the right product quickly. So, you can ship more products faster without the risk of sending the wrong product.

Keeping a detailed record of your products with inventory tracking software will create a more straightforward experience for all. With a system that’s easily accessible through a computer or mobile device, you can keep up to date from anywhere.

That detailed record will also provide a complete history that is assuredly accurate. From an individual part to a large group, you’ll have access to the full archive. You can use the data to analyze patterns and forecast future sales, meaning your company can get a step ahead of your competitors and look to the future.

You’ll also be able to adjust your workflow and processes to fit the growth of your business. As you continue to use the tracking software, you will see efficiency trends in different areas of the process. From there, you can shift scheduling and timing to better suit your workers and how they perform.

It’ll also make giving directives to customers easier for your service department. If a customer needs assistance with their device, they can provide the serial number, allowing you to see exactly what they ordered and provide them with specific details. Should any refund or recall be necessary, you’ll have the information you need, all the way from the manufacturing process to shipping.

In a busy and bustling warehouse, it’s easy to see how anyone could make mistakes. But using serial numbers to keep track of your inventory will provide you and your workers with a more efficient and confident experience.

How to Get Started

If you’re ready to streamline your business with serial number inventory tracking, the best time to get started is now. With automation and access to crucial data on your team, you can keep up with all your company’s needs.

But, before you can move forwards, you need to choose the right computer software. There are so many different types available. To find one that suits your needs, you’ll have to do a little research into what features each brand offers and how they organize their serial number tracking systems.

Some companies will offer you a free trial period to test out their software and see if it’s a good fit. Others provide tutorial videos, showing you exactly how to operate all of the functions and read your data. If the company offers a lot of support on its site, it may be the best choice for beginning a new tracking method.

Most of all, you’ll want to find a company that makes a good business partnership. At Finale Inventory, we pride ourselves on our quality software solutions as well as our customer relations. We want you to have the best experience possible in improving the way your business operates.

Finale Inventory offers everything you need to begin tracking your inventory with serial numbers, including step-by-step videos detailing all of our software’s features and capabilities. Adaptable to any e-commerce business, we create a process that’s tailored to solve your management needs and easily scalable with growth.

You’ll also have a customer relationship manager assigned to your account who will be available to help with consulting, training and program customization at any time. With thousands of customer collaborations, we know the importance of a personalized approach.

We want to show you how much our software can help your business. Create an account and get started with our 14-day free trial — no hassle, no commitment and no cost to you.